Eclore, expert in polymer folding for robotics

From design to production

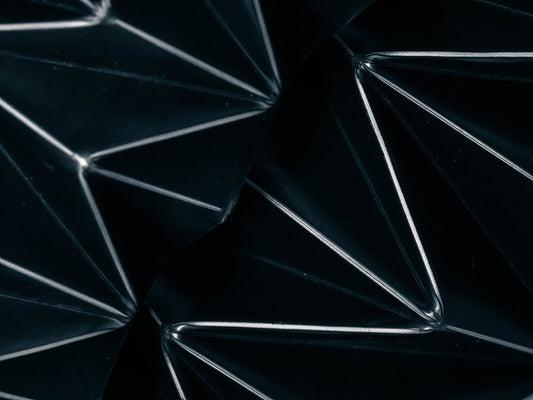

Based in Nantes, France, Eclore innovates with patented folding processes inspired by origami. Our expertise in polymer folding is revolutionising industrial sectors such as aeronautics and aerospace by significantly reducing the weight and size of the products we design, thereby offering solutions at the cutting edge of energy efficiency. Today, we protect your systems. Tomorrow, we'll also be improving your gripping and actuation solutions.

Folding for performance

Find out more-

Compact & light

Folding to reduce space requirements

-

Durable

10 M cycles compressed / deployed

5x more enduring

-

Resistant

Resistant to solvents, oils, UV and impact, high-pressure cleaning

FDA and ISO compliant

-

Adaptable

⌀ from 35mm to 300mm

Watertight so can be operated by pressure and vacuum

To protect your robots

Today, we focus all our expertise on the world of protection to optimise energy performance and extend the life of your industrial systems. Our teams work with you to design solutions tailored to your industrial needs, focusing on durability, lightness and efficiency.

-

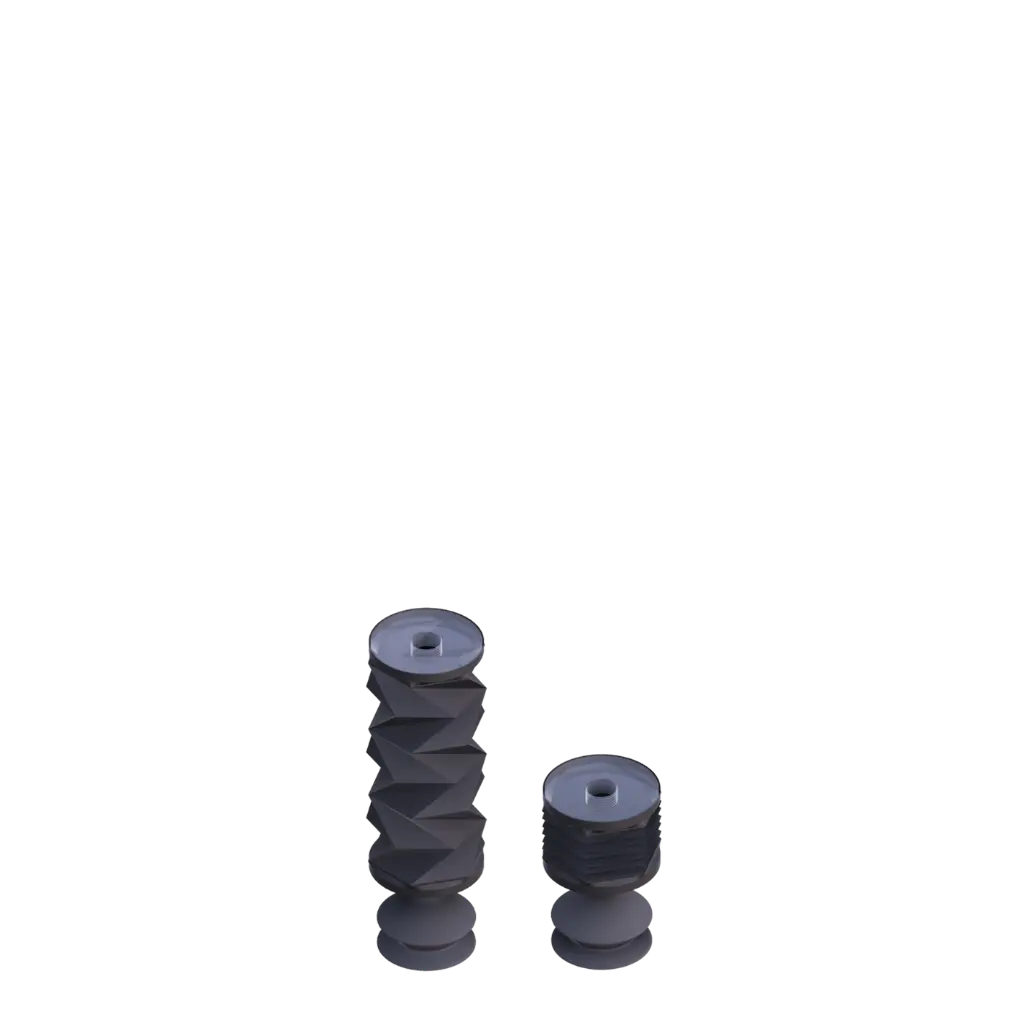

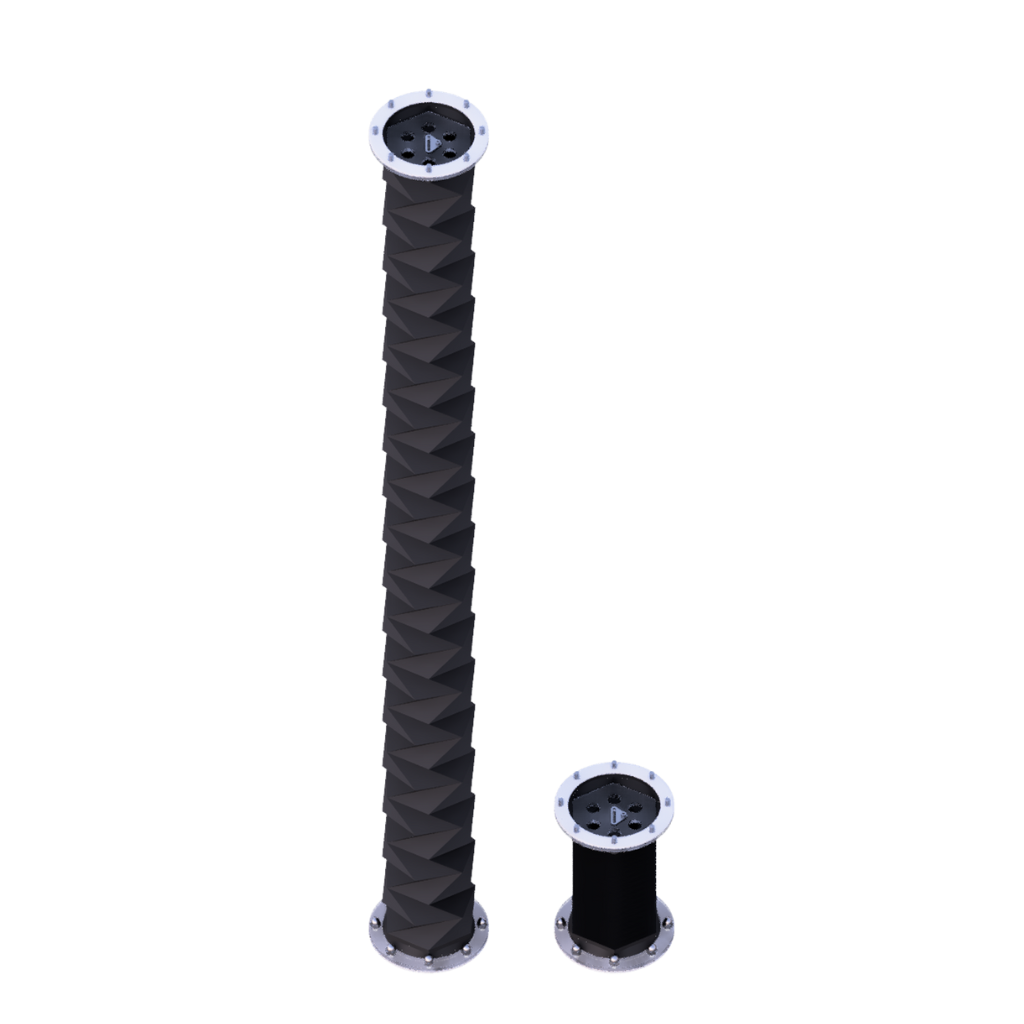

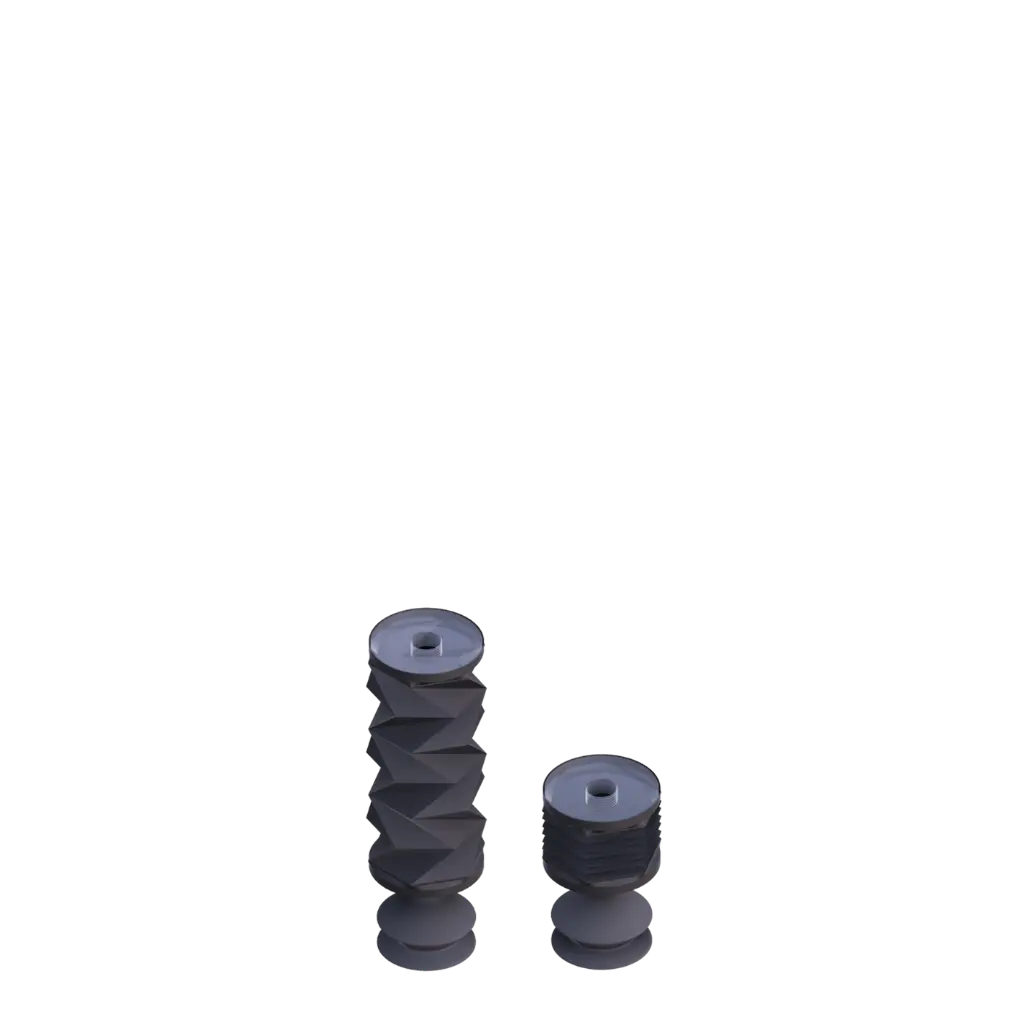

Cylindrical protective bellows

Cylindrical protective bellowsCylindrical protective bellows Your tailor-made bellows Well aware that each application is...

-

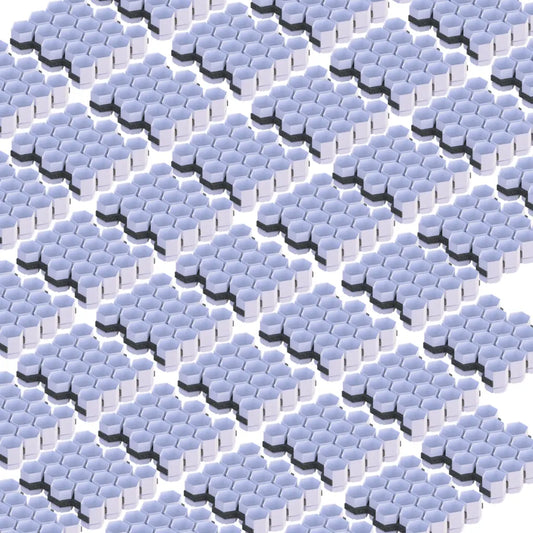

Protection kit for SCARA Robot

Protection kit for SCARA RobotExtend the life of your SCARA robots with the right guards Our...

-

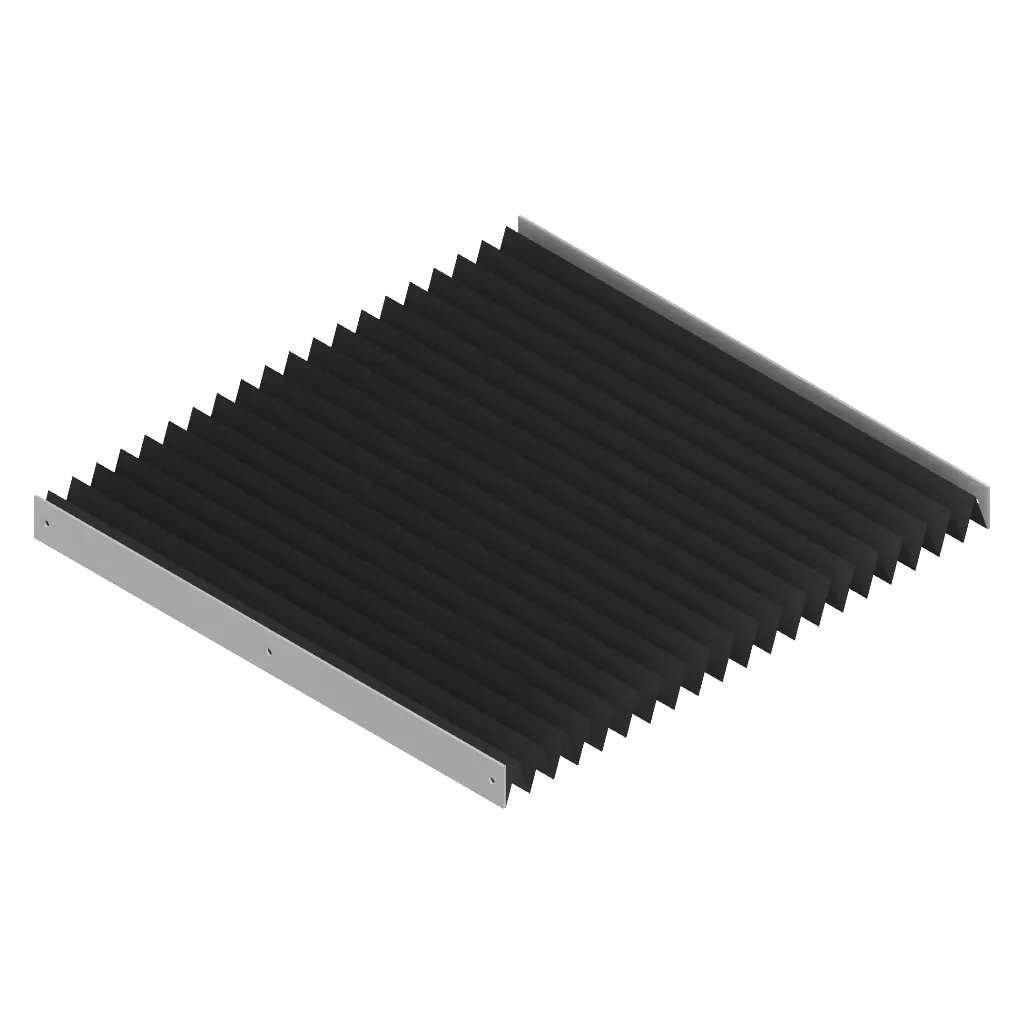

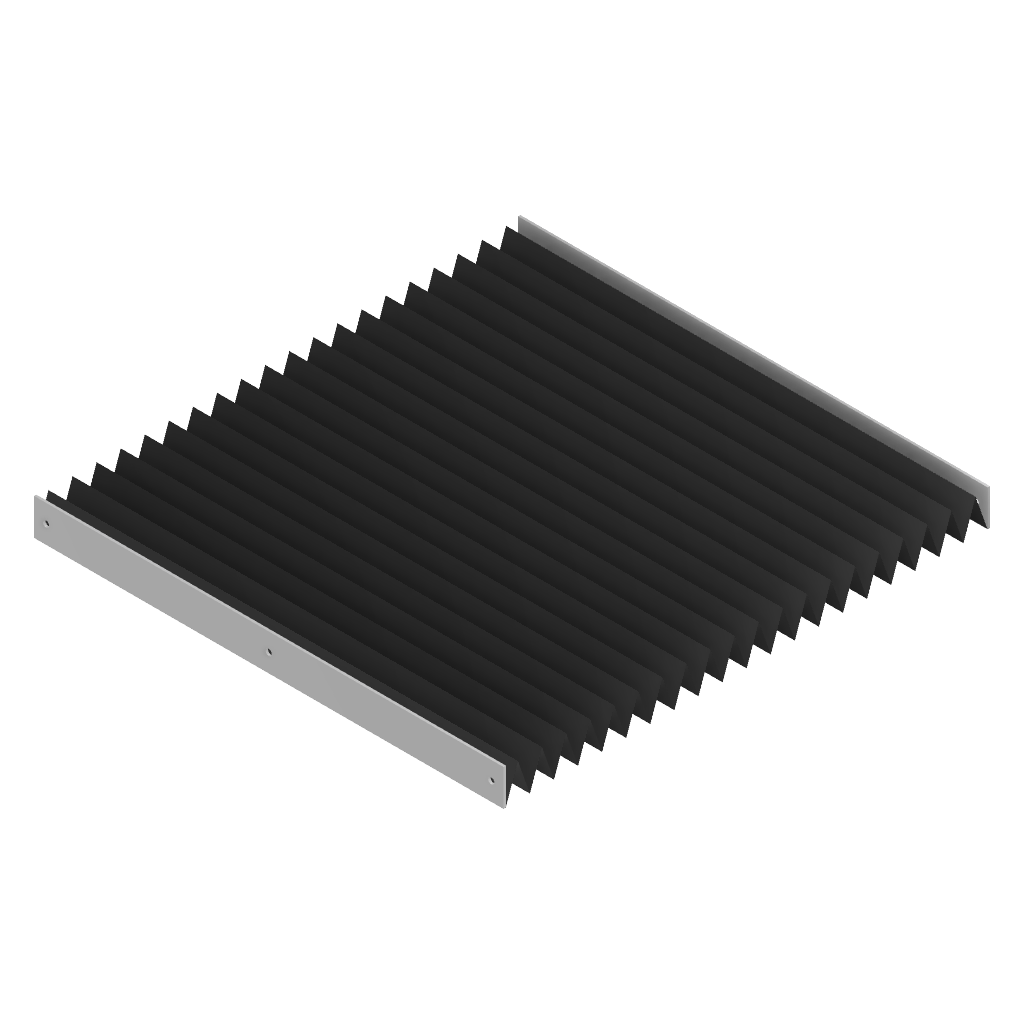

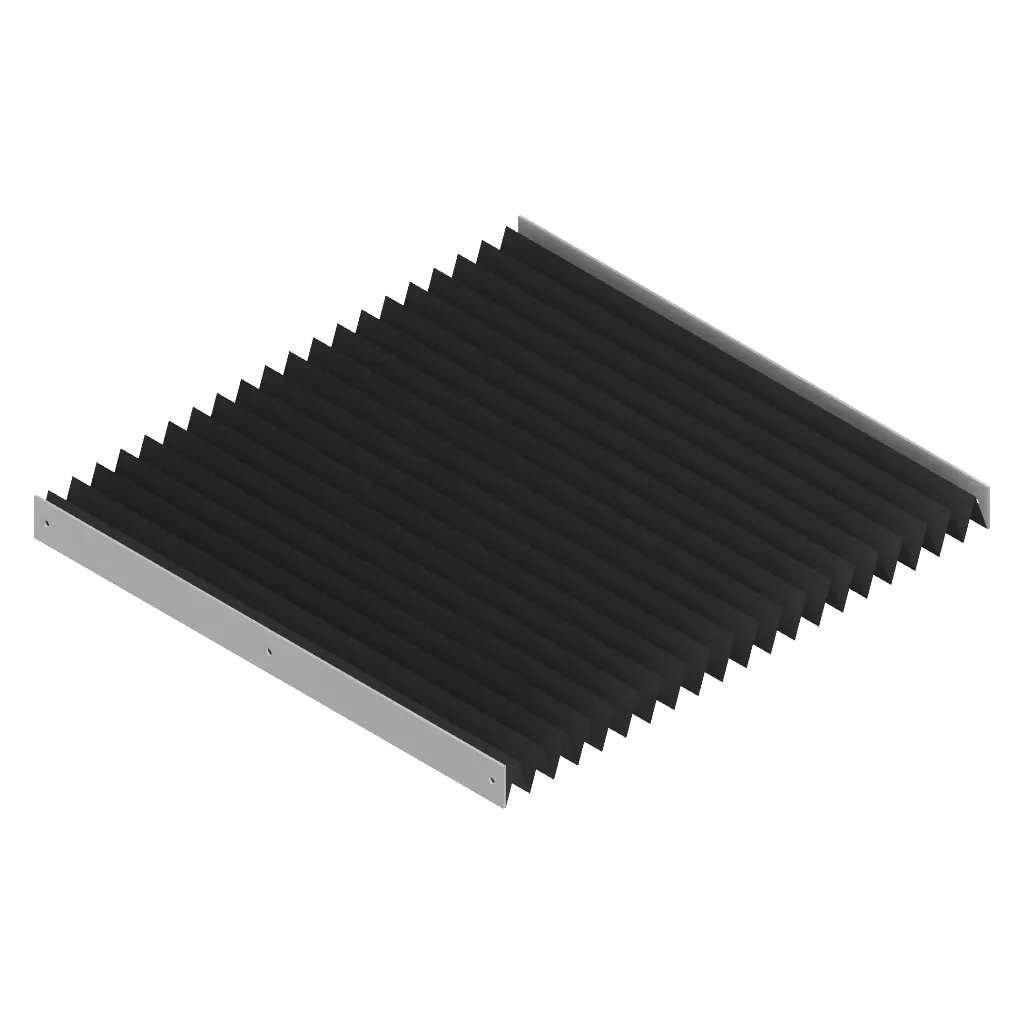

Flat protective bellows

Flat protective bellowsFlat protective bellows Your tailor-made bellows We are fully aware that each...

Our long-term vision

Polymer folding is set to revolutionise industry by providing energy-efficient solutions that are light, compact and strong.

This revolution requires an innovative process,

Eclore has done it!

Future innovations in vacuum lifting

Today, we focus all our expertise on the world of protection to optimise energy performance and extend the life of your industrial systems. Our teams work with you to design solutions tailored to your industrial needs, focusing on durability, lightness and efficiency.

-

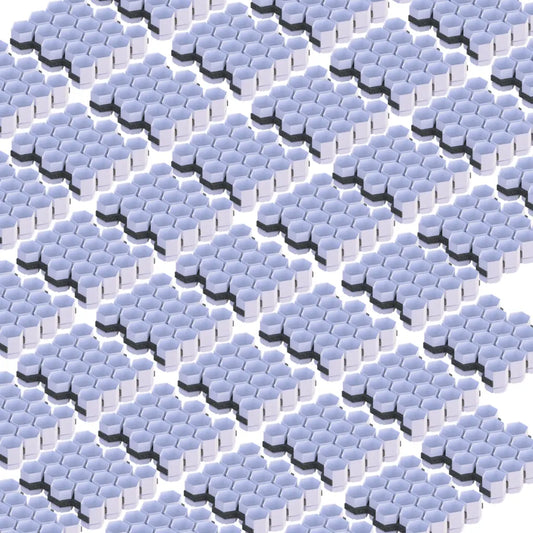

Robot suction gripper

Robot suction gripperThe most versatile robot suction gripper on the market New to the...

-

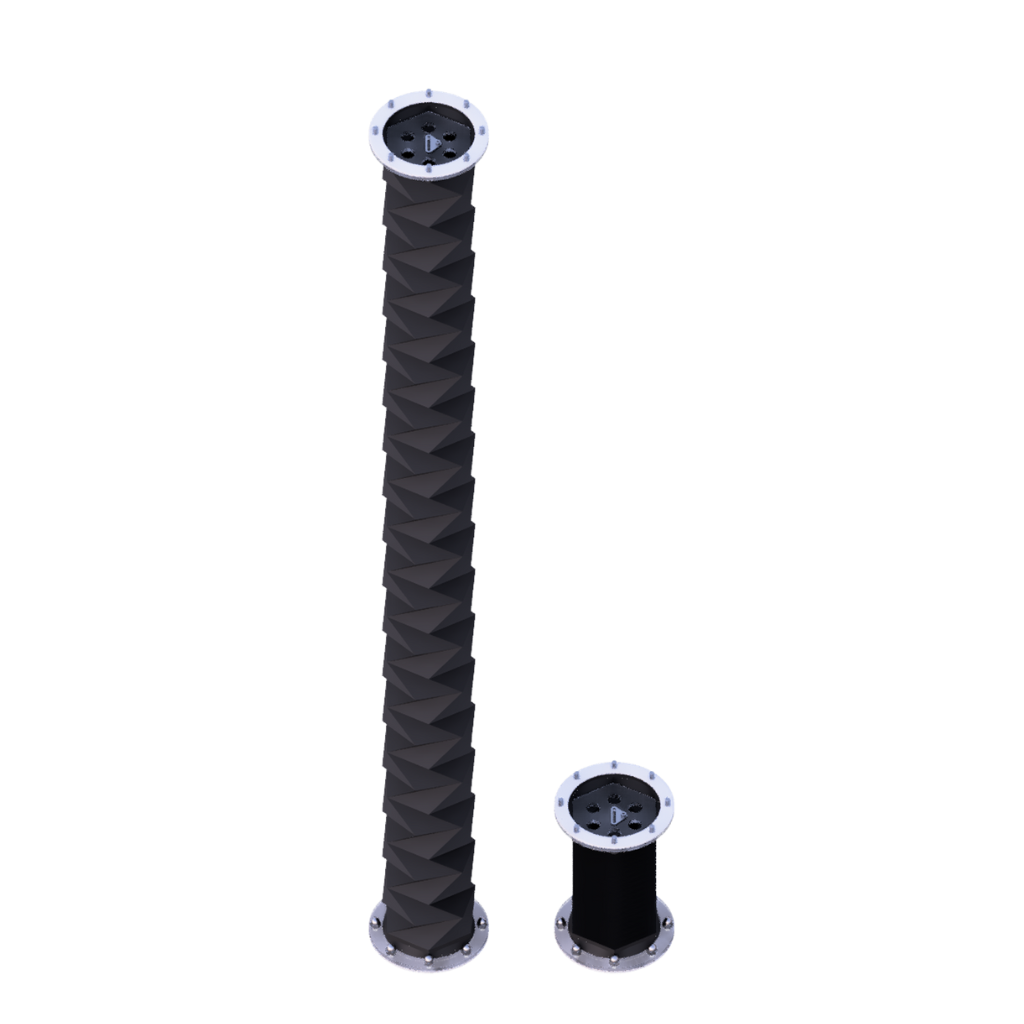

Lifting tube

Lifting tubeVotre tube de levage sur-mesure Nous sommes pleinement conscients que chaque application...

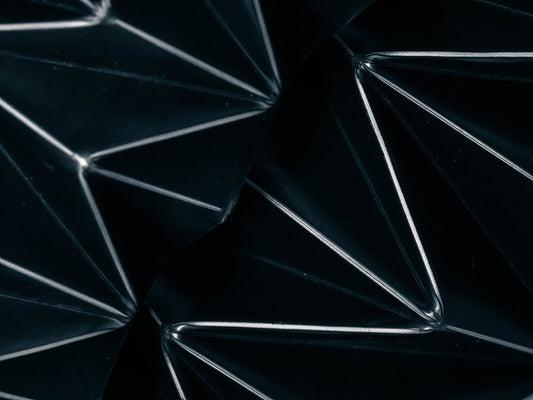

The protective bellow next generation by Eclore

The Eclore bellows: a single base for infinite solutions.

The bellows are the heart of our expertise. Designed using our patented polymer folding process, it is an innovative, durable and modular solution. This flagship product comes in a variety of forms to meet a wide range of industrial needs, offering uncompromising energy efficiency and protection.

Your project is unique, and we are here to support you. Our

design office listens to your needs. Contact us to explore together the opportunities offered by our expertise in polymer folding.

Tailor-made folding solutions for all industries

We specialize in components and solutions to increase energy performance for industry through protection , gripping , actuation and tailor-made solutions .

-

Eclore takes its first steps in Asia: a look ba...

Eclore takes its first steps in Asia: a look ba...Eclore takes its first steps in Asia by showcasing its polymer folding innovations at Tokyo’s iREX 2025. This landmark participation paves the way for new collaborations in the Japanese market.

Eclore takes its first steps in Asia: a look ba...Eclore takes its first steps in Asia by showcasing its polymer folding innovations at Tokyo’s iREX 2025. This landmark participation paves the way for new collaborations in the Japanese market.

-

Lancement du projet LARA – Réduire les nuisance...

Lancement du projet LARA – Réduire les nuisance...Les moteurs, notamment dans les secteurs du transport et de l’industrie, représentent une des principales sources de pollution sonore.Cela entraîne des impacts significatifs sur la santé humaine (troubles du sommeil,...

Lancement du projet LARA – Réduire les nuisance...Les moteurs, notamment dans les secteurs du transport et de l’industrie, représentent une des principales sources de pollution sonore.Cela entraîne des impacts significatifs sur la santé humaine (troubles du sommeil,...

-

How to choose the ideal material for your prote...

How to choose the ideal material for your prote...The choice of material for protective bellows is not a decision to be taken lightly. These components play a vital role in defending your equipment against various external agents, whether...

How to choose the ideal material for your prote...The choice of material for protective bellows is not a decision to be taken lightly. These components play a vital role in defending your equipment against various external agents, whether...